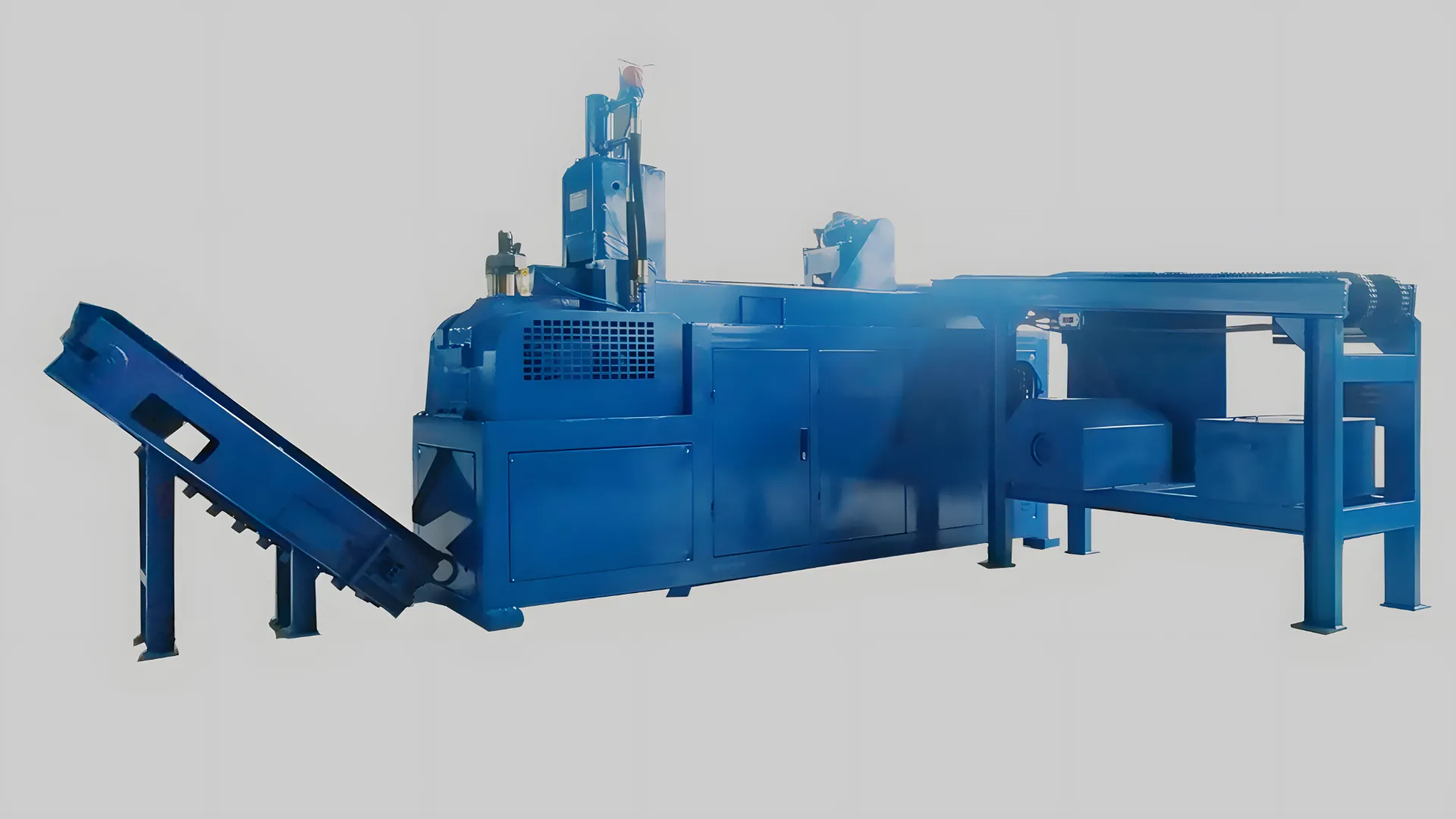

Galvanized iron wire for balers

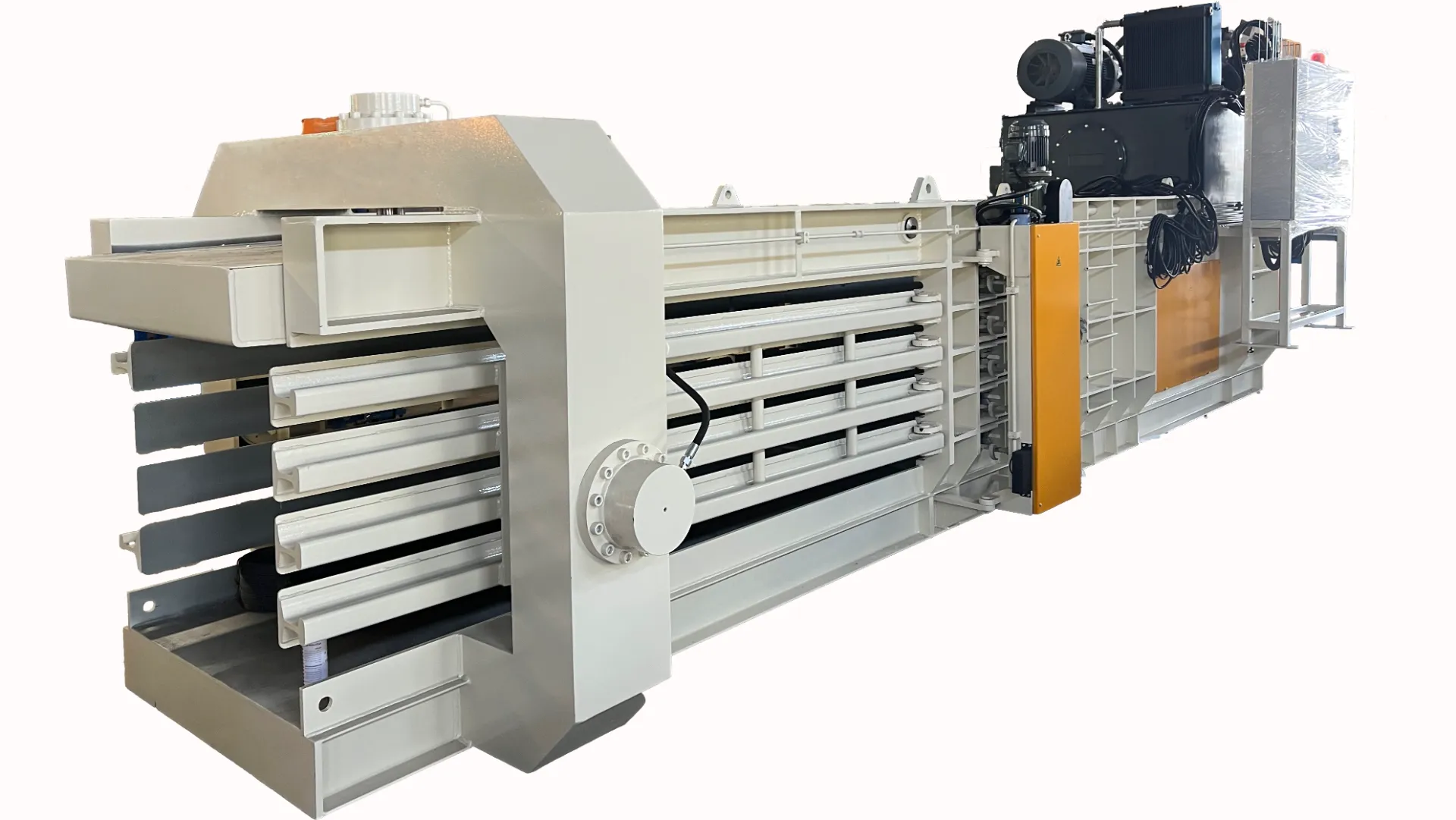

Looking for a reliable way to bind your bales tightly and efficiently? Galvanized iron wire is the perfect solution for a variety of baling applications.This durable wire is specifically designed for use with automatic horizont...