Top Plastic Recycling Machines for Efficient Waste Management

Recycle and reuse mechanical products, protect the environment and save resources.

Learn about the recycling process, methods, equipment and more.

In the plastic recycling industry, effective drying processes are crucial to ensure high-quality output and efficient operations. A Pipe Drying System specifically designed for plastic recycling can significantly improve the drying process, reducing moisture content and enhancing the overall quality of the recycled material. This article explores the key features, benefits, and applications of a Pipe Drying System tailored for plastic recycling.

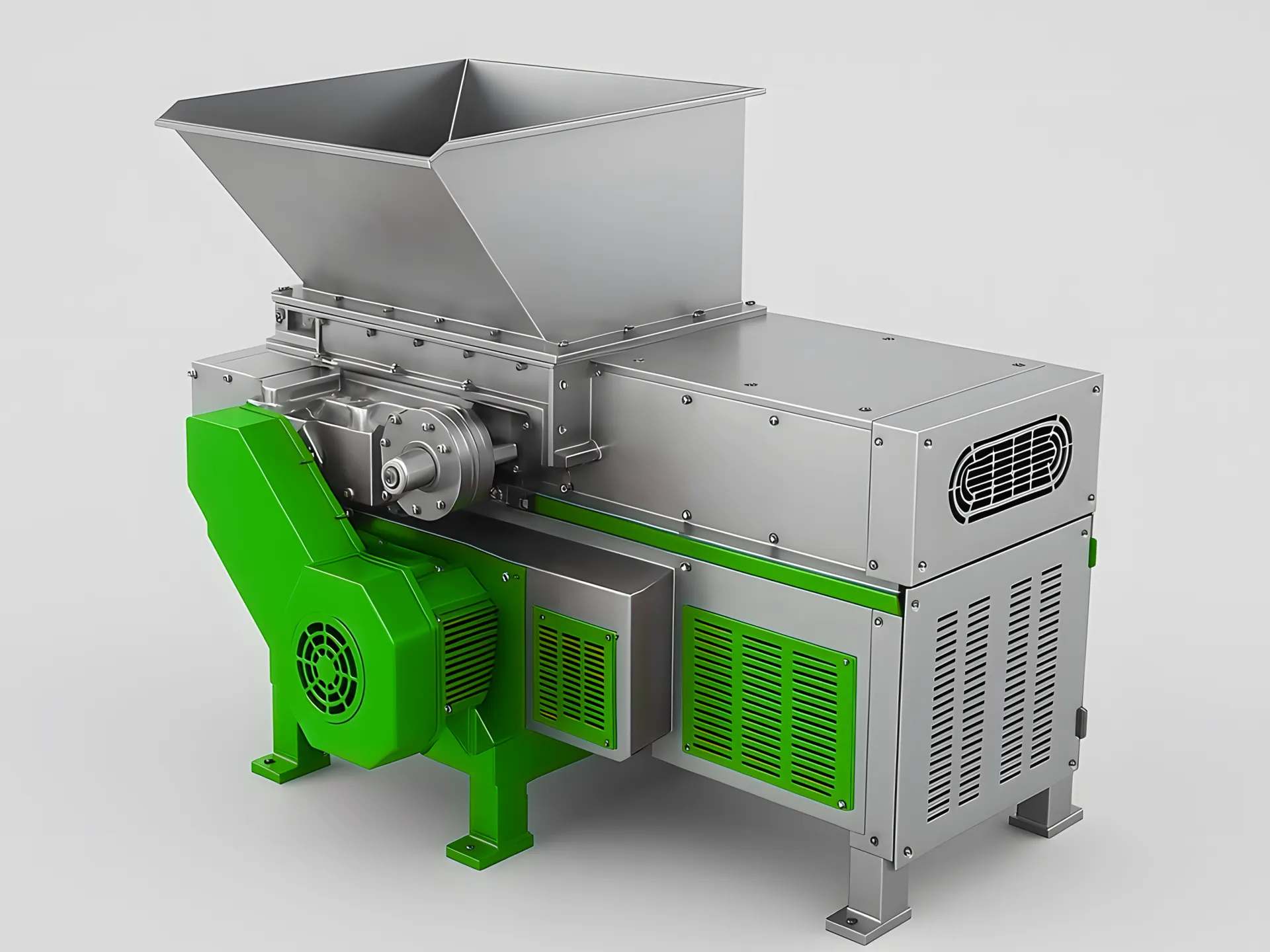

A single-shaft shredder is an essential piece of equipment designed to efficiently handle the shredding of extruder head waste. This machine is built with a robust structure that includes a motor, a reducer with rigid gears, a rotary shaft, imported rotary knives, fixed knives, a sturdy frame, a working platform, a hydraulic ram, and an independent electrical control cabinet.

Recycling post-consumer plastics like PE film, PP woven bags, and agricultural films can be a challenge due to high moisture content. Washed films typically contain up to 40% moisture, which is problematic for recyclers, leading to issues like inconsistent feeding and reduced output in recycling extruders. Traditional drying methods often fail to effectively remove this moisture, leaving up to 30% water content in the materials.