Rumtoo ZM Series Pulverizers are engineered for processing medium-hard, brittle, or high-impact plastics. These machines turn granules into fine powder, achieving a powder consistency between 20 to 100 mesh. The pulverizers are widely used in a variety of industries for grinding different types of plastics, including:

• PE Granules

• PVC Granules

• PC Granules

• Other types of plastics

The materials fed into the pulverizer should be in granular form, with a maximum size of 14 mm.

Features and Design of the Rumtoo TM Series Pulverizers

Rumtoo TM Series Pulverizers are designed for high-capacity performance and feature automatic temperature control to ensure optimal processing. Here’s how they work:

-

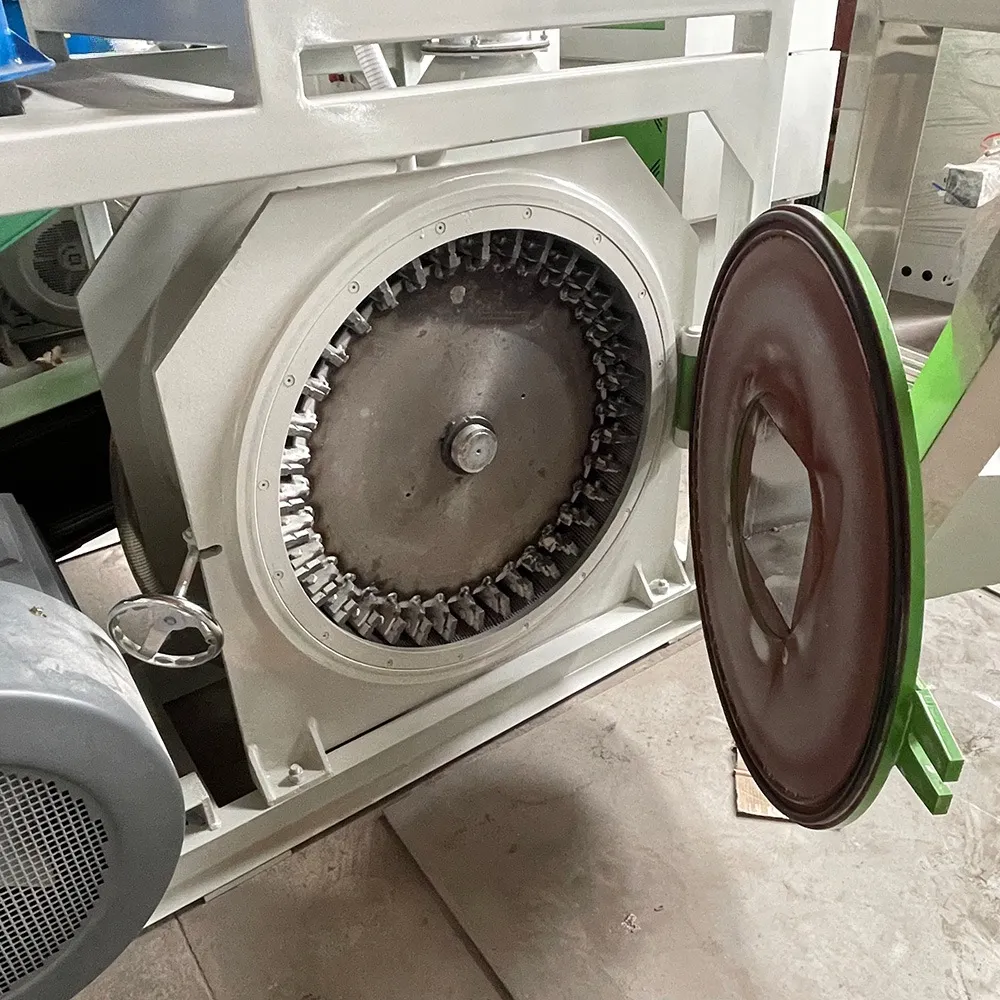

- Feeding Mechanism: The material to be pulverized is introduced into a fixed, high-speed rotating pulverizer disc via a vibrating feeder.

- Centrifugal Force: An integrated inner disc forces the material through the pulverizer disc, pushing it into an external chamber for discharge.

- Material Conveying System: The material is further assisted by a downstream conveying system, ensuring smooth operation.

| Model | Power | Rotating Diameter | Fan Power | Number of Blades | Vibration screen diameter | Production | Equipment Weight |

|---|---|---|---|---|---|---|---|

| TM-500 | 2.2KW | 500mm | 4KW | 12+24 | 800mm | 150-200kg/h | 1500KG |

| TM-600 | 4KW | 600mm | 5.5KW | 13+26 | 1000mm | 200-450kg/h | 2000KG |

| TM-800 | 4KW | 800mm | 11KW | 15+32 | 1200mm | 500-800kg/h | 2800KG |

Pulverizer Operation

Unlike other pulverizers, the Rumtoo TM Series operates without the need for a sifter. The final particle size is primarily determined by the tooth configuration and the adjustable gap between the pulverizer discs. However, if required, a sifter can be added to control the particle size more precisely.

Advantages of the Rumtoo Pulverizer

Rumtoo TM Series Pulverizers offer several benefits, making them a preferred choice for many industries:

-

- High Output: These machines deliver exceptional throughput, making them highly efficient.

- Minimal Thermal Stress: The automatic temperature control reduces thermal stress on the material.

- Longer Disc Life: Pulverizer discs last longer, reducing the need for frequent resharpening and maintenance.

- Easy Adjustment & Replacement: Pulverizer discs can be adjusted or replaced quickly and easily to keep operations running smoothly.

- Cost-Effective: These pulverizers operate economically, lowering production costs.

- Water Cooling System: An internal water cooling system helps maintain optimal temperature during operations, preventing overheating.