How Recycling Balers Can Help Your Business

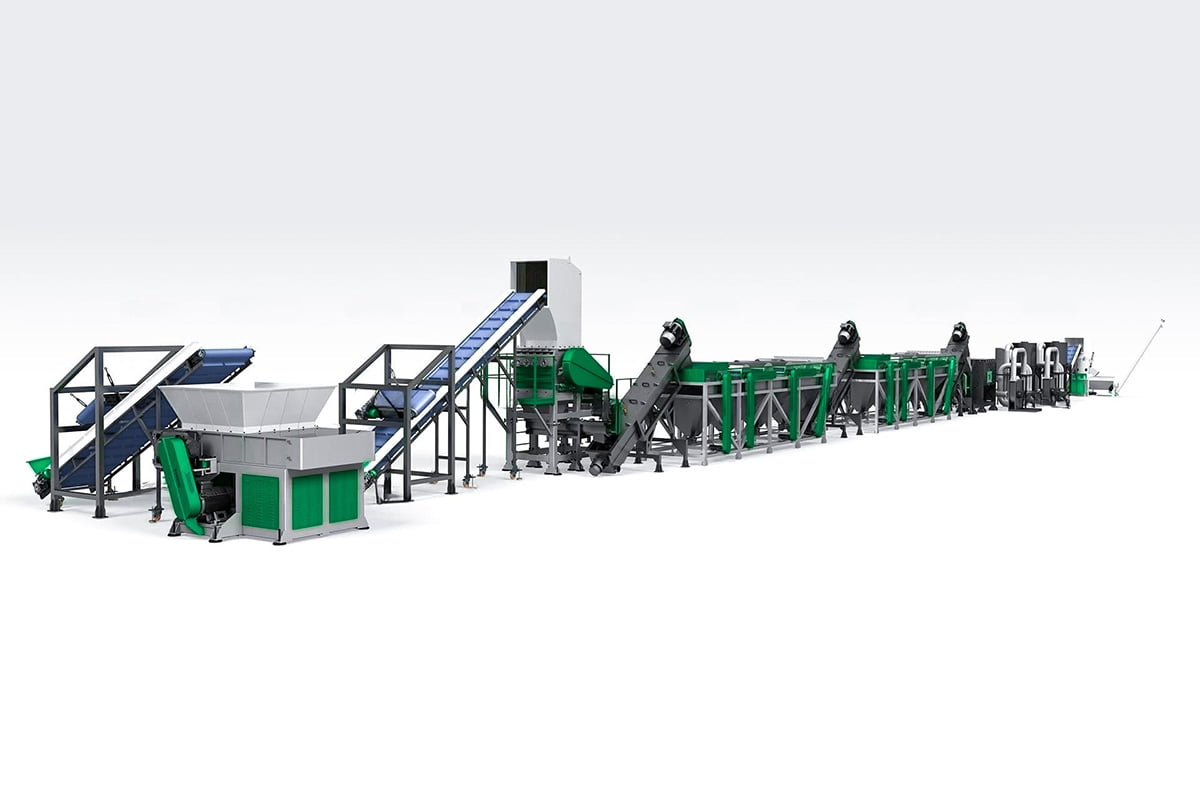

Recycling balers are an essential piece of equipment for any business that generates waste materials. These machines compress waste into compact bales, which can then be easily transported and recycled. Recycling balers offer a nu...

_7.webp)