Kā plastmasas granulēšanas mašīnām ir būtiska loma otrreizējās pārstrādes risinājumos

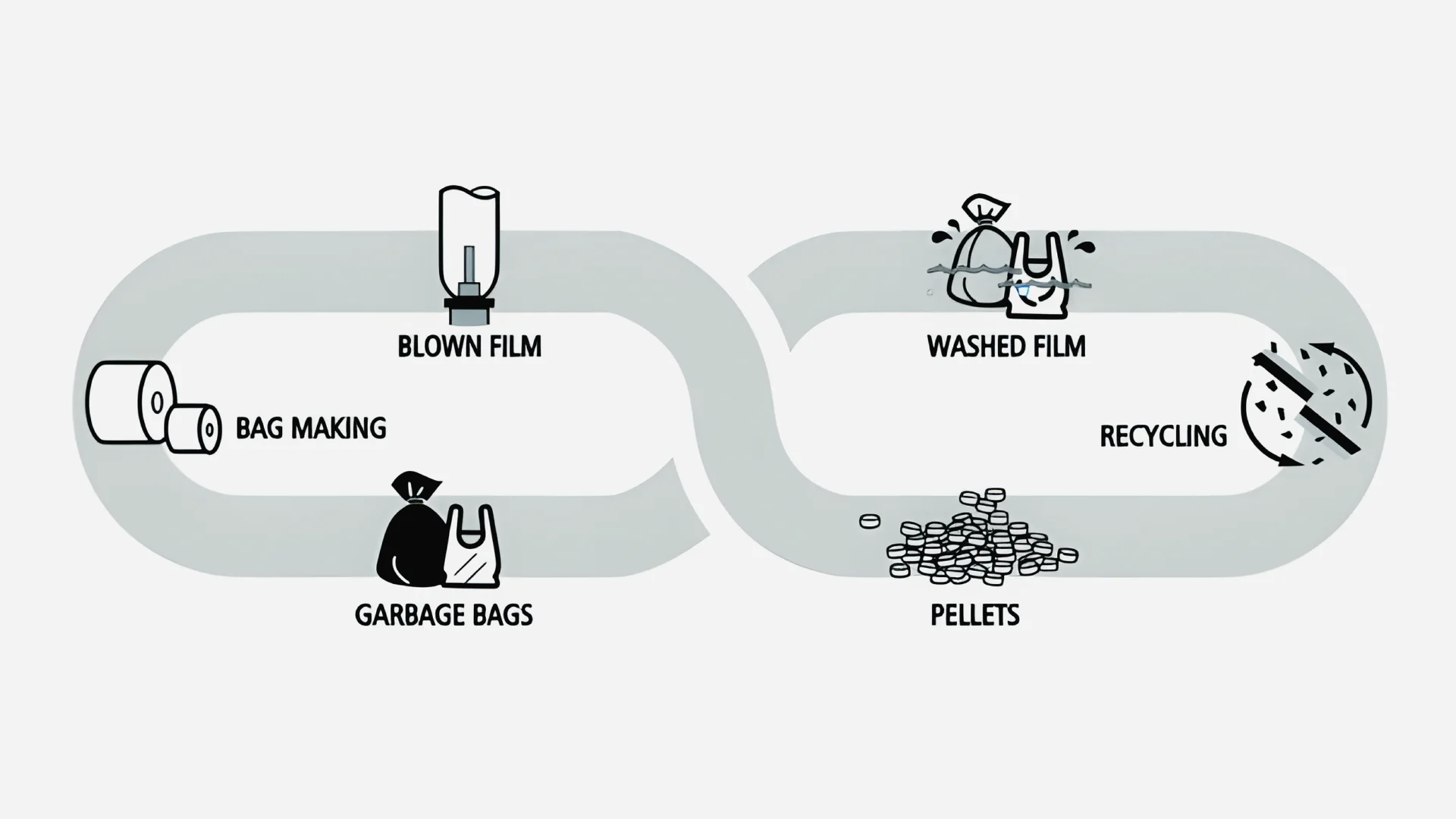

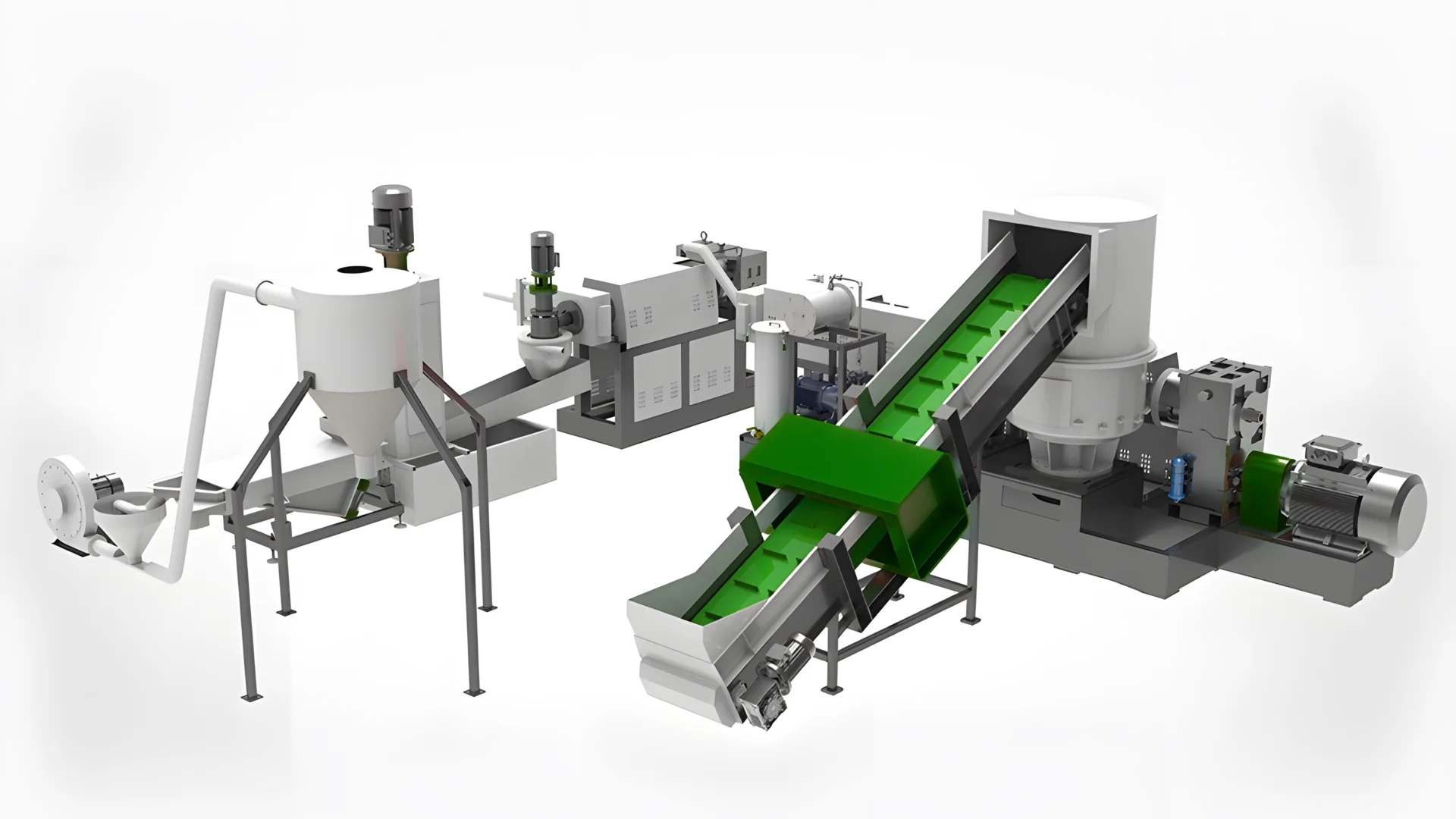

Plastmasas granulēšanas iekārtas ir būtiska sastāvdaļa visaptverošās plastmasas pārstrādes sistēmās, kas darbojas roku rokā ar citām specializētām iekārtām. Lūk, kā tie tiek integrēti otrreizējās pārstrādes procesā, lai izveidotu kompl...