Kā izvēlēties pareizo otrreizējās pārstrādes mašīnu, pamatojoties uz plastmasas atkritumiem

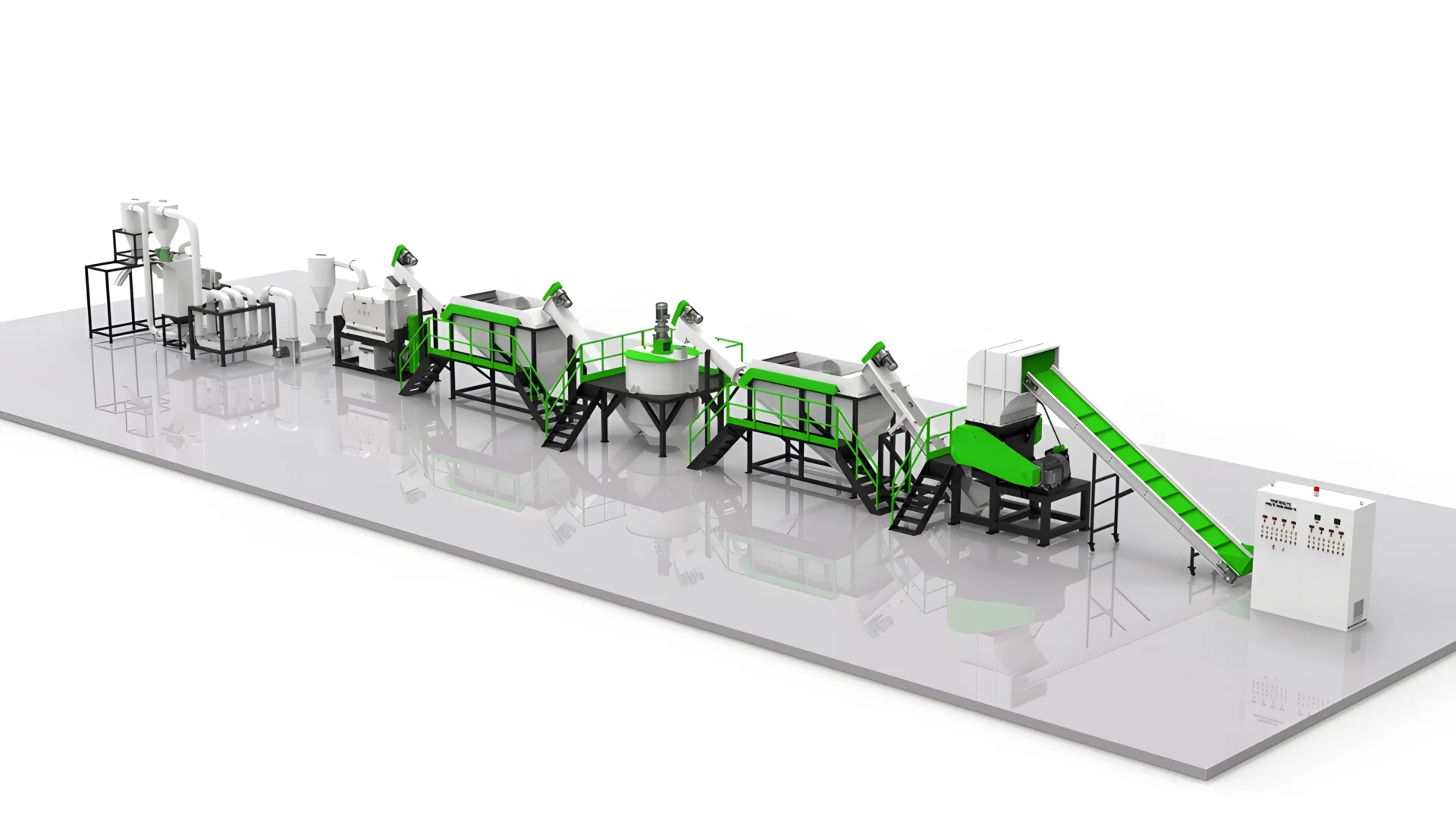

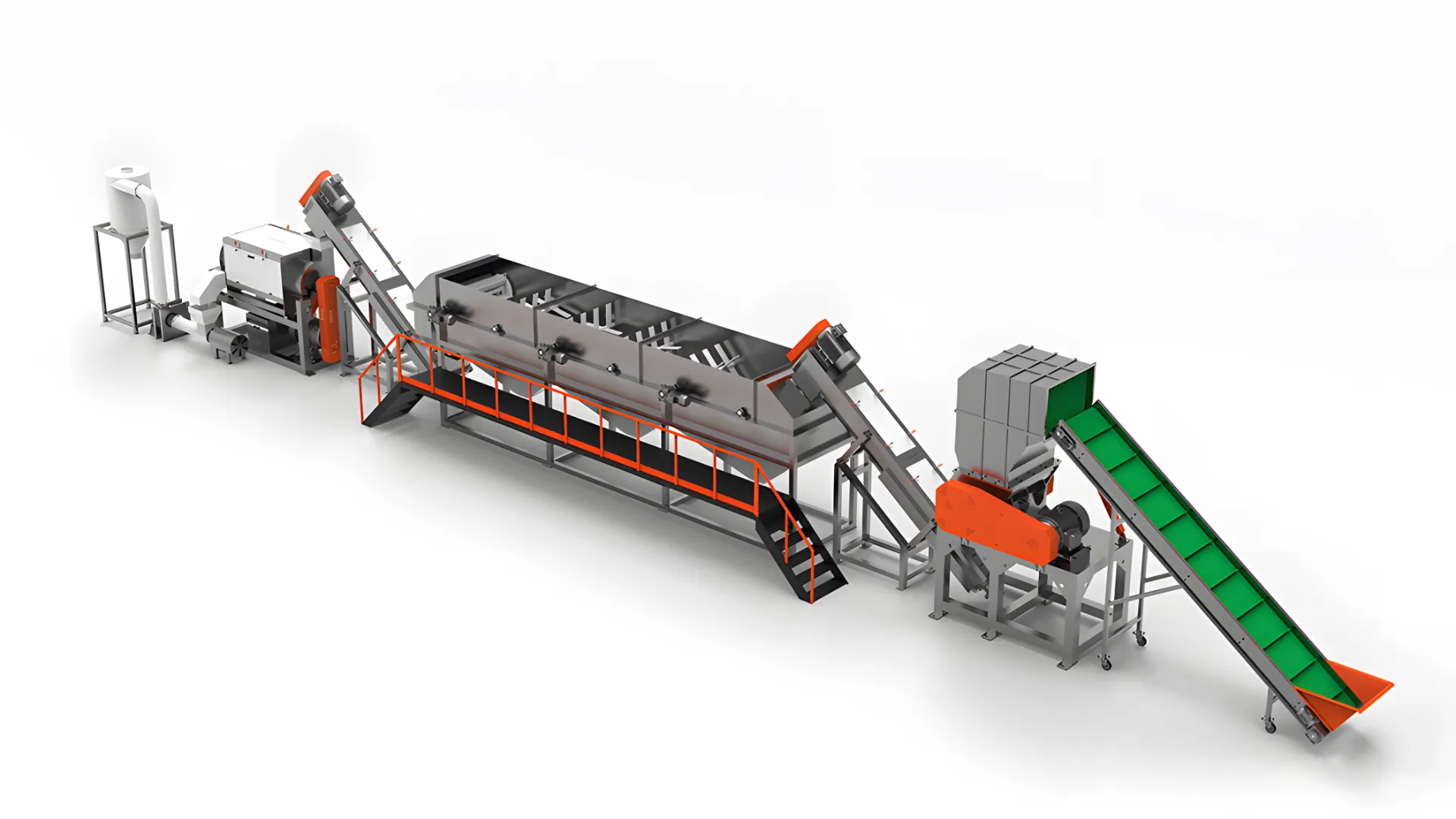

Pareizas pārstrādes iekārtas izvēle ir ļoti svarīga, lai palielinātu efektivitāti un samazinātu atkritumu daudzumu. Tā kā plastmasas izstrādājumiem ir dažādas formas, izmēri un polimēru veidi, to efektīva pārstrāde var būt sarežģīta. Izvēloties...