Centrbēdzes žāvētāja atūdeņošanas mašīna: efektīvi ūdens noņemšanas risinājumi

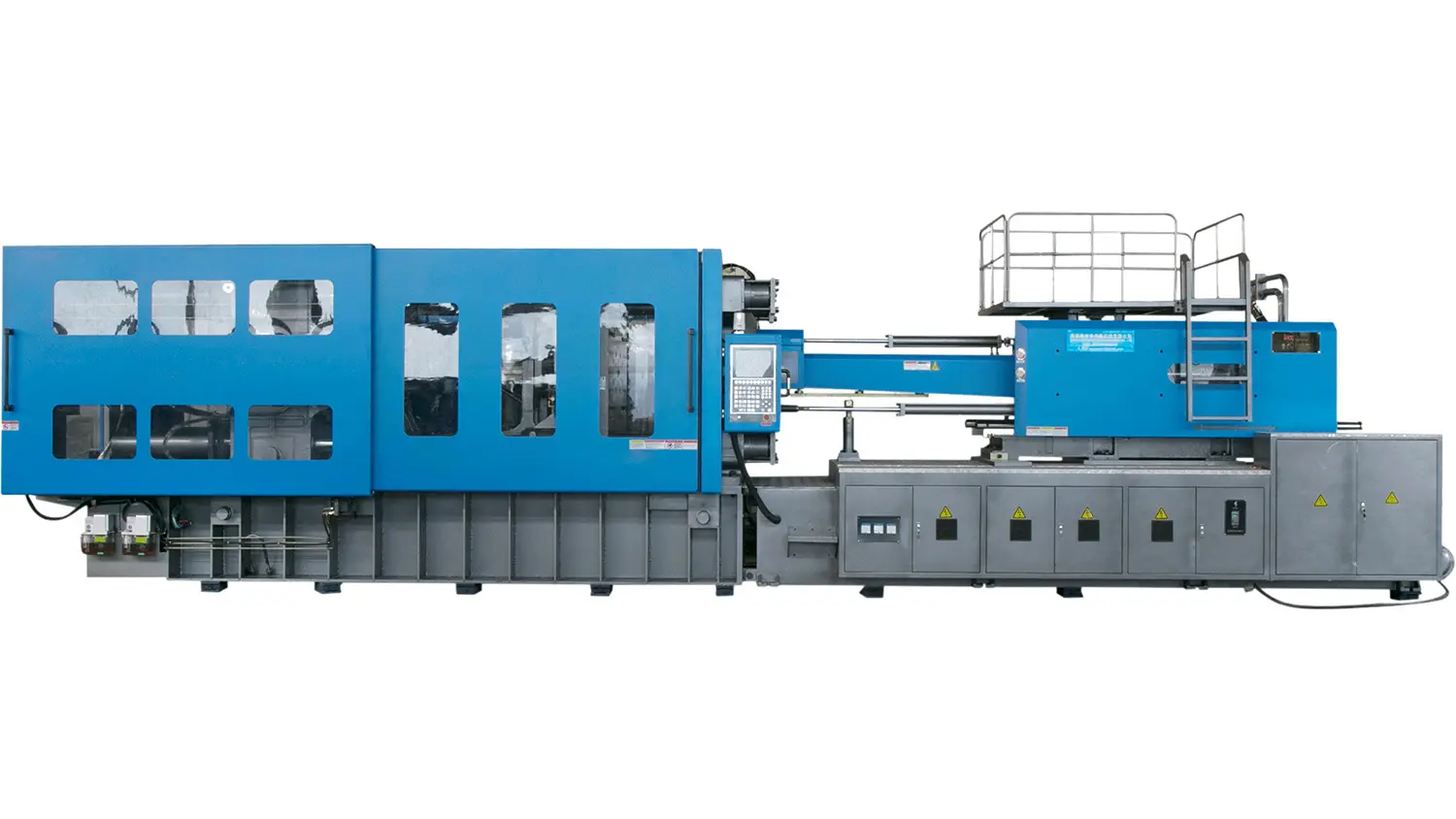

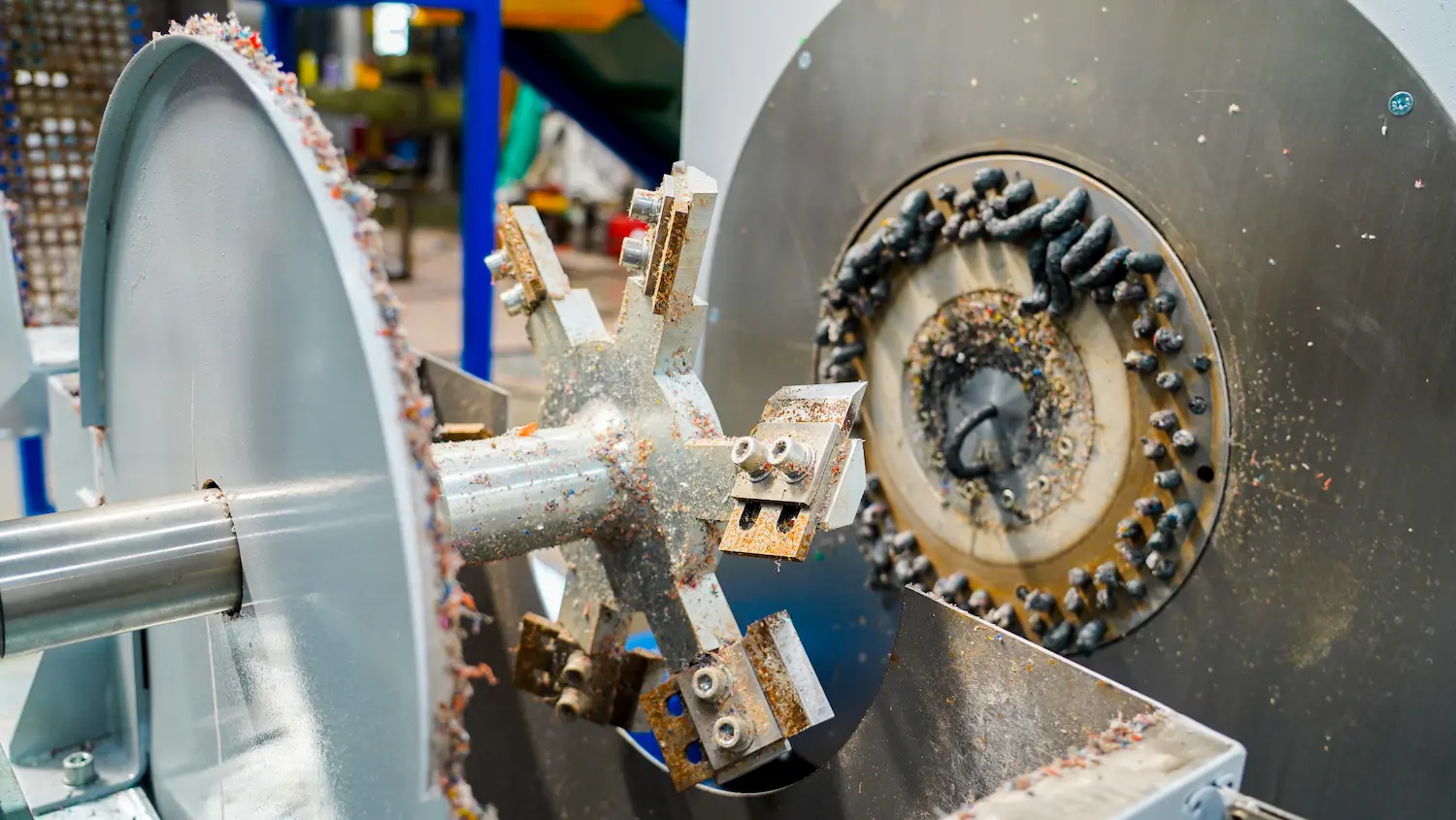

The plastic recycling industry relies heavily on efficient dewatering solutions. Enter the Centrifugal Dryer Dewatering Machine, a crucial piece of equipment designed to remove moisture from plastic materials, ensuring high-qualit...