Vertikālais maisīšanas žāvētājs

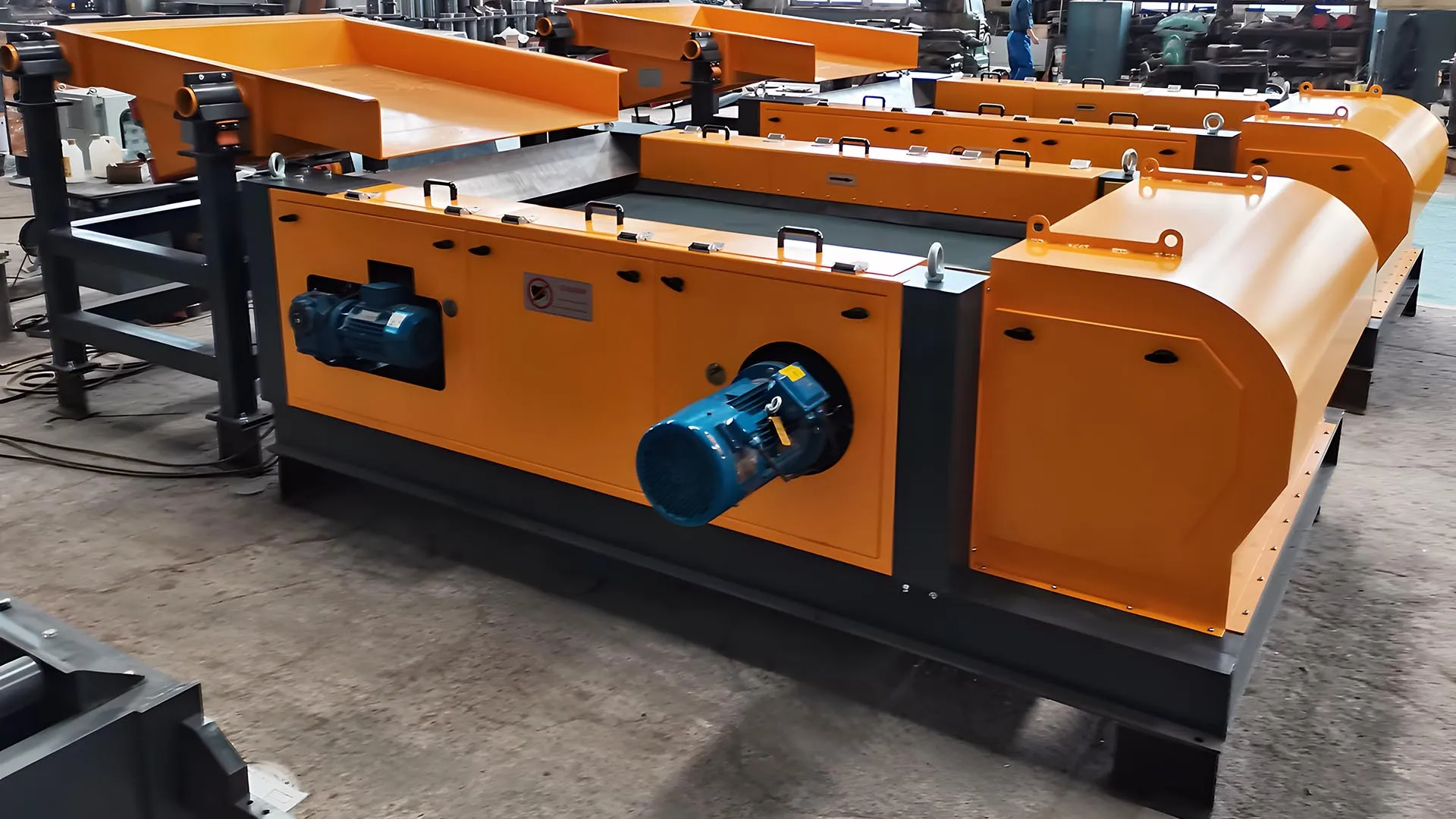

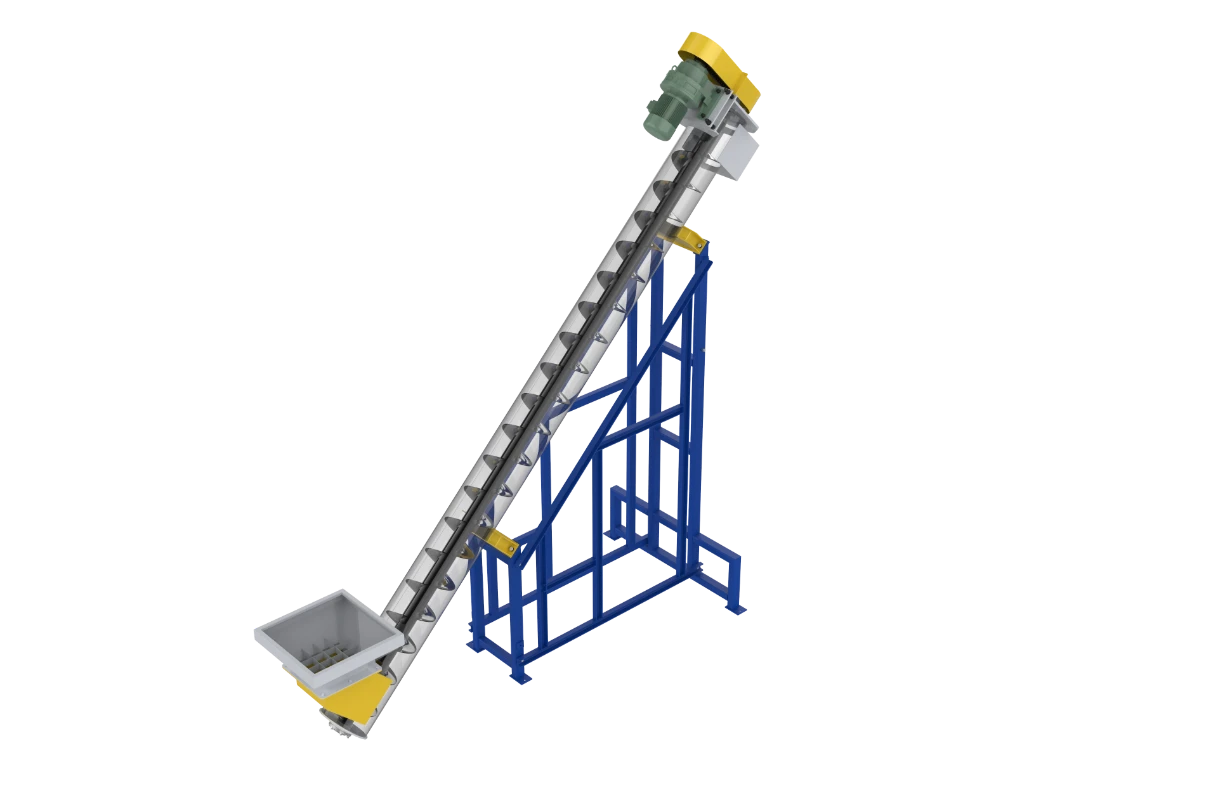

Vertical Mixing Dryer Overview A vertical mixing dryer, also known as a lifting stirring dryer or a granular blending machine, utilizes rotating mixing blades to agitate plastic raw materials, achieving rapid mixing of granular...