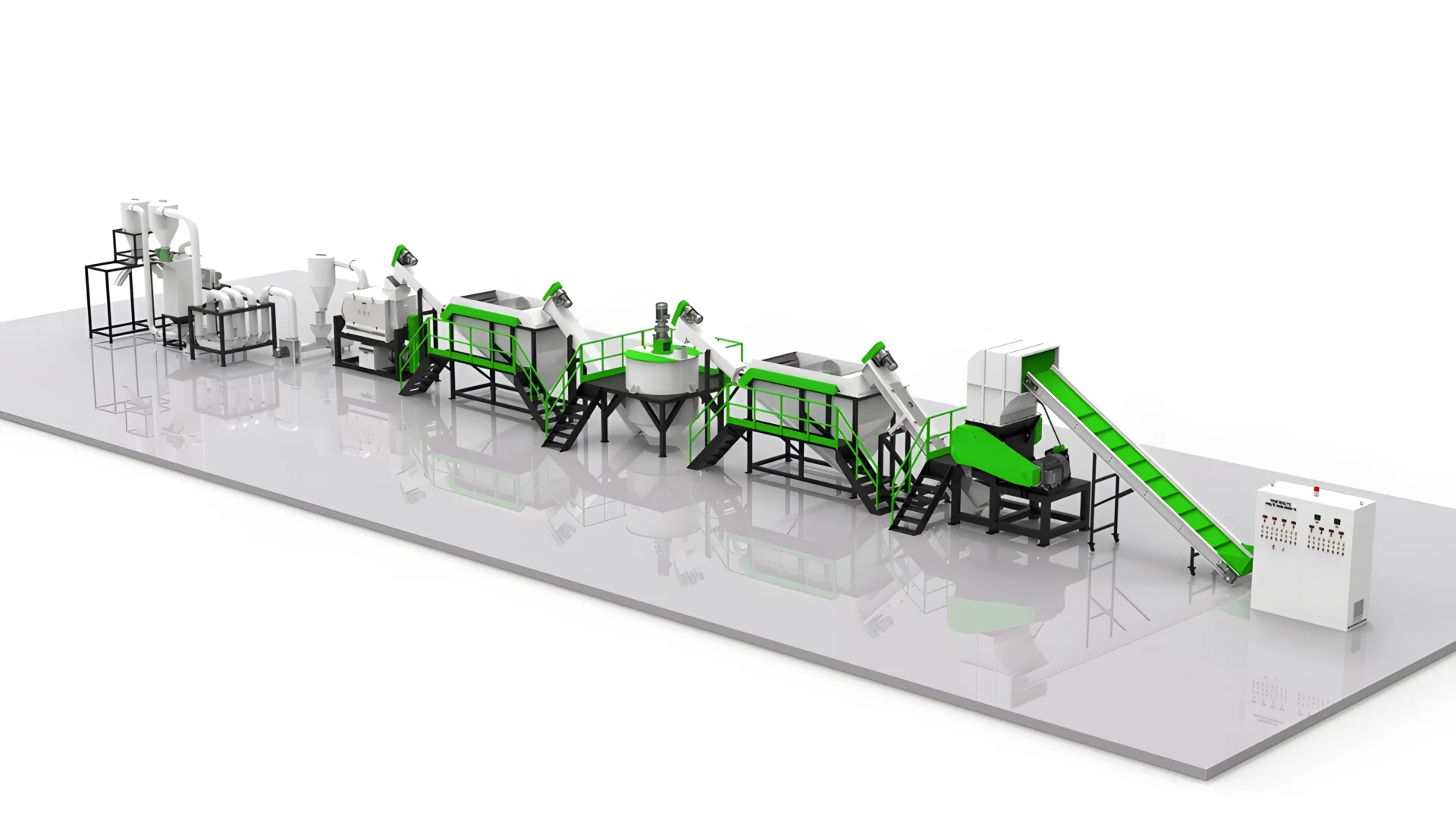

Plastic recycling line

Our state-of-the-art technology enables efficient processing of various types of plastics, ensuring maximum recovery and minimal waste. From shredders to granulators, we offer a full range of machines that handle everything from collection and sorting to reprocessing and pelletizing.

Advanced Recycling Technology

Compact and Modular Design

User-Friendly Interface

Robust Material Handling System

Energy Efficiency and Sustainability

Full Support and Maintenance

Šis video sniedz visaptverošu ieskatu PE plēves pārstrādes mazgāšanas līnijas procesā un tā priekšrocībās.

Videoklips sākas ar kadriem, kuros redzami izmestie PE plēves atkritumi, uzsverot otrreizējās pārstrādes nozīmi. Pēc tam mēs jūs aizvedīsim uz progresīvu PE plēvi otrreizējās pārstrādes mazgāšanas līnija, kurā parādīti šādi galvenie procesi:

Introduce

In this video, we take you through the comprehensive process of washing PP PE rigid regrinds, showcasing the efficiency and effectiveness of the entire system. The video begins with the High-Speed Friction Washer, where intense friction removes contaminants and prepares the material for further cleaning. Next, we demonstrate the Sink-Float Separation stage, a critical step that separates heavier contaminants from the plastic using differences in density.

Comprehensive Plastic Recycling Equipment List with Detailed Specifications

This detailed list outlines the essential machinery and equipment used in a high-efficiency plastic recycling production line. The list includes specifications for belt conveyors, granulators, screw conveyors, separators, washing tanks, thermal dryers, de-watering machines, and more. With a total installed power of 310KW and a production capacity of 1,000 to 1,500 KG/h, this equipment setup is designed for optimal performance in plastic recycling processes. Perfect for businesses aiming to enhance their recycling operations.

This is our standard 500 KG/H PET bottle washing line, specifically designed for our clients in the United States. Employing the most advanced technology and equipment, this line ensures efficient and high-quality PET bottle recycling processes. Our washing line features comprehensive capabilities that meet stringent environmental and production standards, aimed at providing our clients with the best recycling solutions and maximum economic benefits. Additionally, we offer customization services to accommodate diverse operational needs and site conditions for each client.

This HDPE, PP, and PS rigid plastic washing plant is designed to thoroughly clean contaminated rigid plastics, including HDPE/PP bottles, lumps, and other rigid materials. This comprehensive recycling solution includes a robust shredder with an overhead magnet, granulator, sink-float separation tank, centrifugal dryer, thermal dryer, zig-zag separator, and a dual-bag filling station. The resulting premium-quality plastic flakes can be reused in manufacturing plastic products.

The entire line is designed to clean shredded PP/PE regrind, featuring a friction washer, floatation tank, centrifugal dryer, squeezer, extruders, and pellet cutting system. Below are explanations for some of the key machines:

A significant amount of melt-blown sheets are left over during production, so we developed this line to recycle the excess melt-blown sheets for reuse. The finished pellets can be used to make premium plastic bags and other polypropylene (PP) products.