生産効率と製品品質の向上を目指すメーカーにとって、適切なプラスチックペレタイザーを選択することは非常に重要です。このガイドでは、処理する材料の種類、生産能力、エネルギー効率など、プラスチックペレタイザーを選択する際に考慮すべき重要な要素について説明します。

コンテンツ

Understanding Plastic Pelletizers

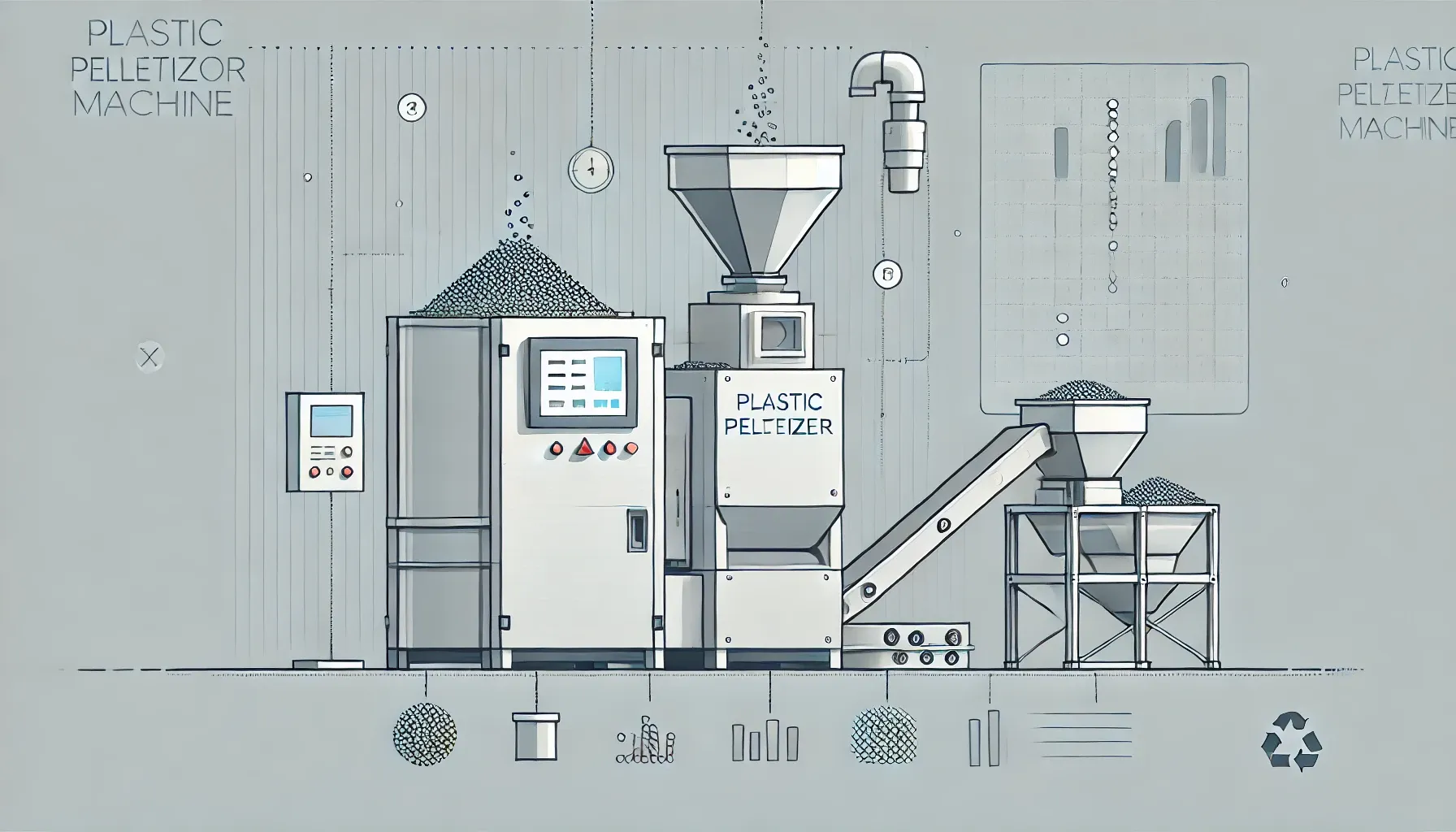

Plastic pelletizers are essential in converting plastic raw materials into uniform pellets, which are easier to handle and process in various manufacturing applications. Here are some critical aspects to consider:

Types of Materials Processed

The type of plastic material you’re working with significantly influences your pelletizer choice. Common plastics include:

- ポリエチレン(PE)

- ポリプロピレン(PP)

- ポリ塩化ビニル(PVC)

- ポリスチレン(PS)

- Engineering Plastics (ABS, Nylon, etc.)

Each material has different melting points, viscosities, and handling requirements. Ensure the pelletizer you choose is compatible with the specific type of plastic you intend to process.

Production Capacity

Production capacity is a vital consideration for manufacturers. It’s essential to select a pelletizer that meets your output requirements without compromising quality. Factors influencing capacity include:

- Machine Size and Design: Larger machines typically offer higher capacities.

- Feed Rate: Ensure the pelletizer can handle the feed rate of your production line.

- Pellet Size and Uniformity: Consistent pellet size is crucial for downstream processing.

エネルギー効率

Energy efficiency is a critical factor affecting both operational costs and environmental impact. Consider the following:

- Motor Efficiency: High-efficiency motors reduce energy consumption.

- Heating Systems: Advanced heating systems can enhance energy efficiency.

- Operational Settings: Machines with adjustable settings allow optimization for different materials and conditions, improving overall efficiency.

Additional Considerations

メンテナンスと耐久性

Regular maintenance ensures the longevity and performance of your pelletizer. Look for machines with:

- Durable Components: High-quality materials and construction.

- メンテナンスの容易さ: Accessible parts for easy cleaning and servicing.

- Support and Spare Parts: Availability of spare parts and manufacturer support.

Automation and Control

Modern pelletizers often come with automated features and advanced control systems. Benefits include:

- Consistency: Automated systems ensure uniform pellet quality.

- 使いやすさ: User-friendly interfaces simplify operation.

- Data Monitoring: Advanced systems provide real-time monitoring and data analysis for better process control.

Cost

While initial investment is a consideration, focus on the total cost of ownership, including:

- Energy Costs: More efficient machines may have higher upfront costs but lower long-term energy expenses.

- Maintenance Costs: Durable machines with low maintenance requirements can save money over time.

- Production Efficiency: Higher efficiency and productivity can offset initial costs.

結論

正しい選択 プラスチックペレタイザー involves evaluating the type of materials processed, production capacity, and energy efficiency. By considering these factors and additional aspects such as maintenance, automation, and cost, manufacturers can make informed decisions tailored to their specific needs.