Skrúfupressuafvötnunarkerfið okkar, hannað sérstaklega fyrir PE filmu þvottalínuna okkar, er mjög áhrifarík aðferð til að draga raka úr efnisstraumi. Reyndar eru skrúfupressurnar okkar oft notaðar í matvælavinnslu, pappírs- og kvoðaiðnaði, skólphreinsun og fleira. Þessi endingargóða vél veitir framúrskarandi rakaminnkun án verulegs kostnaðar (rafmagnskostnaðar) við að nota hitauppstreymi.

Starfsregla

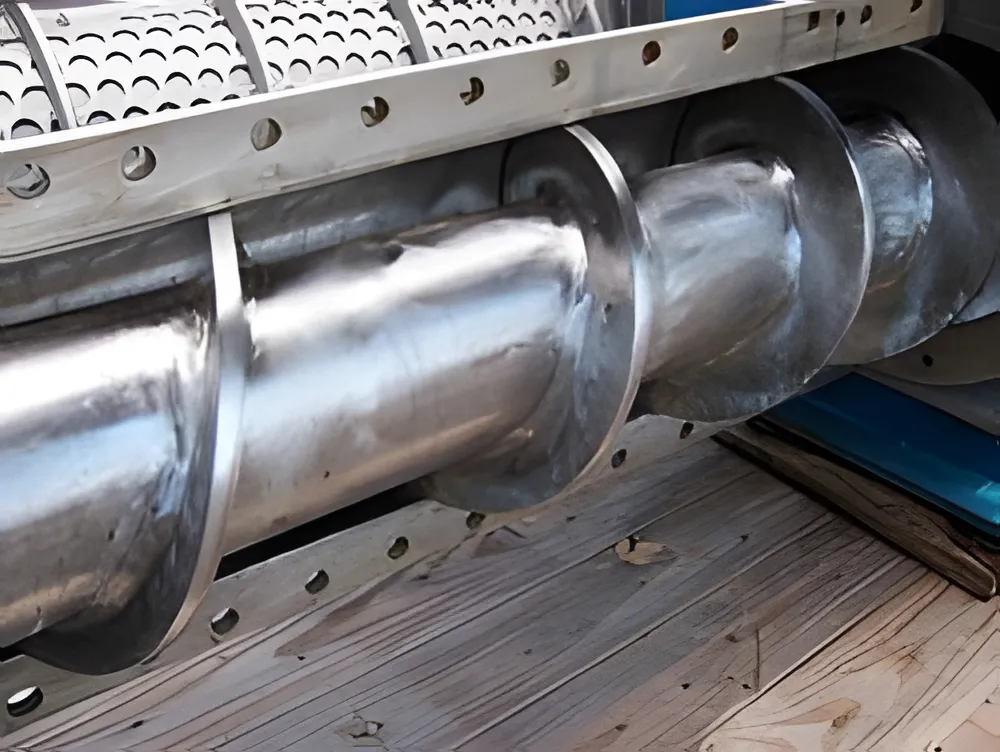

Kjarninn í afvötnunarkerfi skrúfupressunnar okkar er skrúfuskaft með stigvaxandi þvermál. Skrúfuskaftið er þrengst við inngangsstaðinn þar sem plastefnið er flutt inn um lóðrétta fóðrið. Umhverfis skrúfuskaftið er þykkveggað ytra rör með jöfnum þvermál fóðrað með götum fyrir vatnsrennsli. Dæmigerð afvötnunarskrúfapressa fyrir endurvinnslu í iðnaði er 4-6 metrar að lengd en hægt er að stilla hana í samræmi við kröfur þínar.

Þegar blautu plastfóðrið er komið inn í fóðrið, snýst skrúfaskaftið smám saman og ýtir plastinu áfram. Eftir því sem þvermál skrúfuskaftsins eykst, þjappast plastið í auknum mæli saman við ytri hlífðarvegginn. Rakinn úr plastefninu er kreistur út og rennur í gegnum litlu götin.

Við lok láréttu skrúfupressunnar er þvermál skrúfuskaftsins aðeins minna en innra þvermál ytri hlífarinnar. Það er í gegnum þetta þrönga bil sem þurrkað plastefni fer út úr skrúfupressunni. Vel hönnuð skrúfapressa mun draga úr rakainnihaldi niður í viðunandi magn undir 15%.

Viðbótar myndir

Spyrðu núna

Til að fá nýjustu verð og afgreiðslutíma, sendu okkur skilaboð með því að nota formið hér að neðan.