Fully Automatic Plastic Disc Grinding Machine: Efficient Grinding of PVC Plastic Pellets into 20-100 Mesh Powder

What Are Plastic Grinding Machines?

Plastic grinding machines are essential tools for grinding and processing plastic materials. These machines are a cornerstone of modern plastic recycling and manufacturing industries.

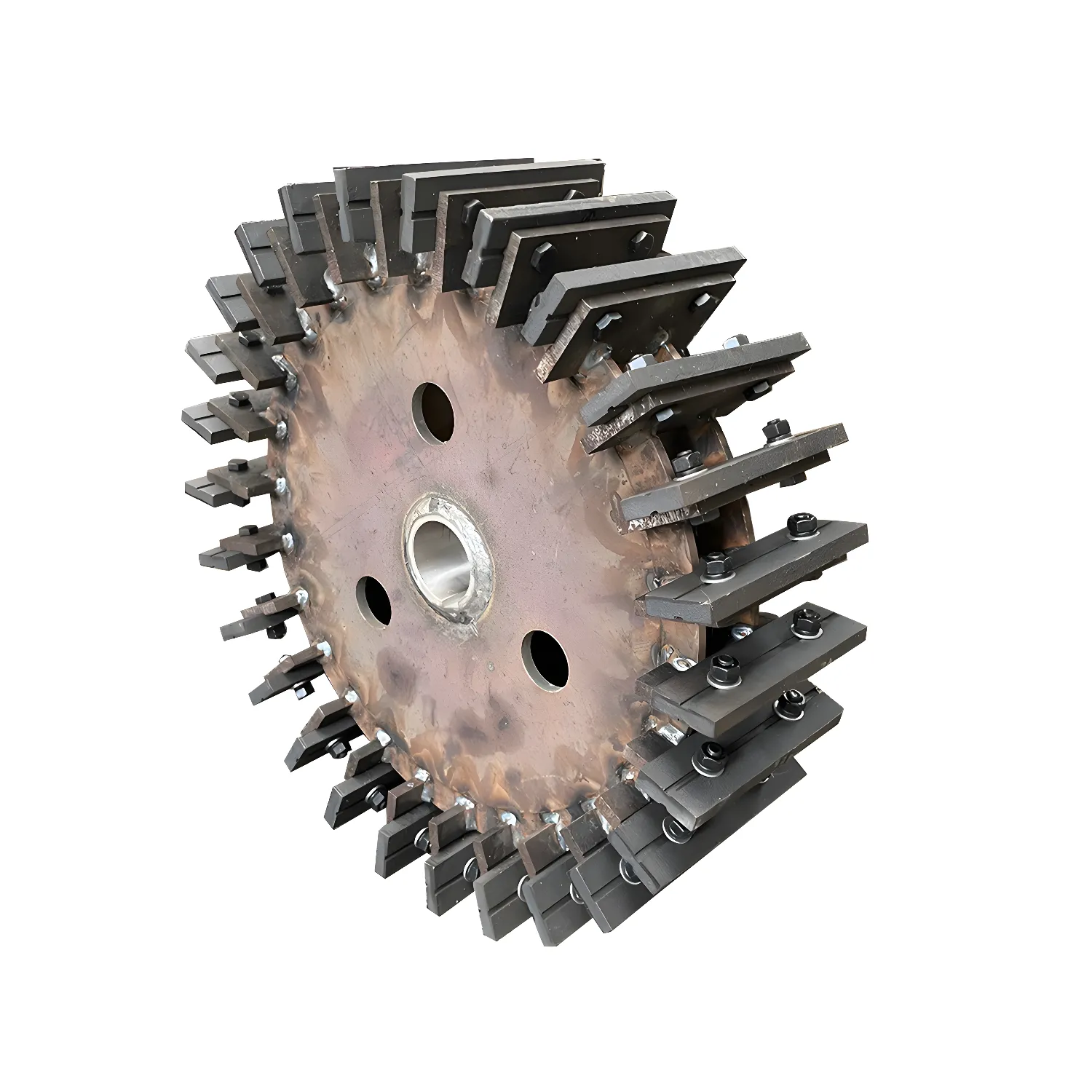

- Disc Grinding Machines: Operate by grinding and cutting materials using the gap between two precision-engineered grinding discs.

Advanced Design and Development

Our plastic grinding machines are designed with the latest technology, incorporating advanced features inspired by international equipment. They meet customer needs for processing a wide range of thermoplastic materials, including:

- PVC

- High-density PE

- PS

- SBS

- Foamed PE

- EVA

- Soft PVC

- Plant fibers

- Leather

These machines are indispensable for recycling plastic waste, enabling manufacturers to manage excess materials efficiently while lowering production costs.

Key Advantages of Plastic Grinding Machines

Plastic grinding machines offer numerous advantages, making them a superior choice for plastic processing:

- High Output: Deliver exceptional performance with maximum efficiency, ensuring fast production.

- Low Energy Consumption: Save energy without compromising the quality of grinding.

- Adjustable Grinding Mesh Sizes: Tailor the output to your specific needs, with precision control for particle sizes.

- Perawatan Mudah: Simplify upkeep with user-friendly design features that reduce downtime.

- Environmentally Friendly Operation: These machines are designed to operate without causing pollution, supporting sustainable manufacturing practices.

Compared to similar equipment, plastic grinding machines provide enhanced performance, catering to practical user needs while promoting cost-effective and eco-conscious operations.

Parameter teknik

| Model | Kekuatan | Rotating Diameter | Fan Power | Jumlah Bilah | Vibration Screen Diameter | Produksi | Berat Peralatan |

|---|---|---|---|---|---|---|---|

| MF-500 | 2.2 KW | 500 mm | 4kW | 12 + 24 | 800 mm | 150–200 kg/h | 1500 KG |

| MF-600 | 4kW | 600 mm | 5,5 KW | 13 + 26 | 1000 mm | 200–450 kg/h | 2000 KG |

| MF-800 | 4kW | 800 mm | 11 KW | 15 + 32 | 1200 mm | 500–800 kg/h | 2800 KG |