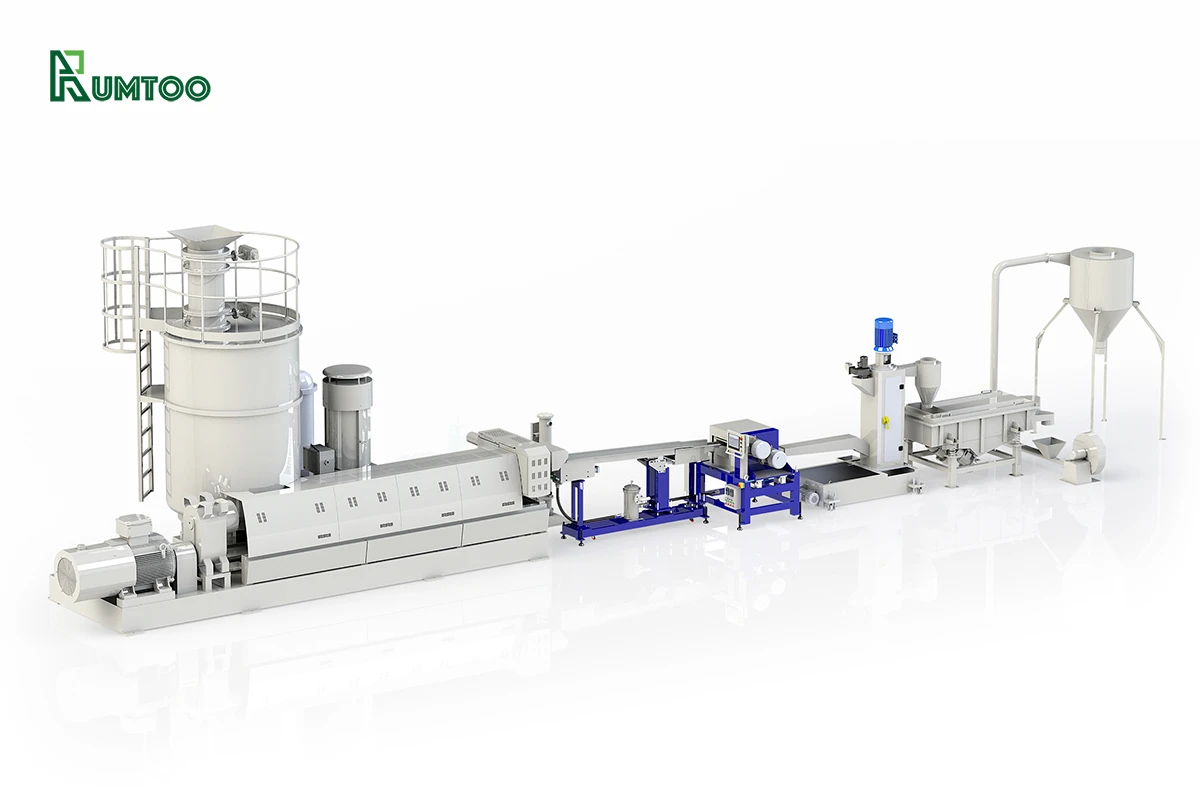

Rumtoo PP/PE Film Pellet Machine

Efficient. Durable. Future-Ready. Transform plastic waste into profit with Rumtoo’s advanced pelletizing solutions.

In today’s rapidly evolving recycling industry, the PP/PE-kalvopellettikone by Rumtoo stands as a symbol of innovation and sustainability. Built to process materials such as HDPE, LDPE, LLDPE, PP, PS, PET, and PC, this machine is engineered to produce clean, reusable plastic pellets that meet international quality standards.

Why Choose Rumtoo’s Pellet Machine?

- Multiple Screw Designs: Allows continuous and stable production across different plastic types.

- Advanced Cooling System: Integrates wind blowing, water cooling, and dewatering technologies for optimal pellet consistency.

- Flexible Storage: Stainless steel containers are adjustable for different batch sizes.

- Scalable Output: Capacity ranges from 200–1000 kg/h, ideal for startups and large-scale plants alike.

How the Plastic Pelletizing Line Works

The pelletizing process transforms plastic film waste into clean, reusable pellets through a series of carefully designed steps:

- Murskaaminen/murskaus: Breaks down waste plastic into smaller fragments.

- Washing & Drying: Removes contaminants and moisture to prepare for extrusion.

- Ekstruusio: Melts the plastic and pushes it through a precision die.

- Pelletointi: Cools and cuts the extruded plastic into uniform pellets.

- Cooling & Final Drying: Ensures pellets are moisture-free and ready for use.

- Screening: Removes undersized particles and dust for quality assurance.

- Pakkaus: Final step for storage or transportation.

Environmental & Economic Benefits

Rumtoo’s PP/PE pellet machine helps tackle one of the world’s largest waste challenges—plastic pollution. By recycling plastic film waste into high-quality pellets, you not only reduce landfill dependency but also cut costs on virgin raw materials. The result? Higher profits and a cleaner planet.

Main Technical Parameters

For detailed specs, refer to the table below:

| Malli | RMC2-85 | RMC2-100 | RMC2-120 | RMC2-150 | RMC2-160 | RMC2-180 |

|---|---|---|---|---|---|---|

| Kapasiteetti (KG/H) | 100-200 | 200-300 | 300-400 | 500-600 | 700-800 | 800-1000 |

| L/D | 1:33 | 1:33 | 1:33 | 1:36 | 1:36 | 1:36 |

| Asennusteho (KW) | 110 | 135 | 160 | 310 | 370 | 520 |

| Puristusteho (KW) | 37 | 45 | 55 | 110 | 132 | 180 |

| Pääekstruuderin teho (KW) | 55 | 75 | 90-110 | 185 | 220 | 280-315 |

| Näytön vaihdin | 160 mm | 200mm | 250 mm | 350mm | 400mm | 500+mm |

| Henkilöstövaatimus | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| Kokonaiskoko (P*L*K) | 9*5*4 | 10*5*4 | 12*5*4 | 13*6*4 | 13*6*4 | 13*6*4 |

We are confident that Rumtoo’s PP/PE film pellet machine will help you meet your production targets and exceed your clients’ quality expectations.

✅ Warranty

All Rumtoo recycling systems include a 1-year limited warranty, covering key components and full technical support.

Pyydä tarjous

Contact us today to receive pricing, lead times, and layout design for your Rumtoo pelletizing system.