Rumtoo ZM Series Pulverizers er konstrueret til behandling af mellemhård, skør eller slagfast plast. Disse maskiner gør granulat til fint pulver og opnår en pulverkonsistens mellem 20 og 100 mesh. Pulverisatorerne bruges i vid udstrækning i en række industrier til formaling af forskellige typer plast, herunder:

• PE Granules

• PVC Granules

• PC Granules

• Other types of plastics

The materials fed into the pulverizer should be in granular form, with a maximum size of 14 mm.

Features and Design of the Rumtoo TM Series Pulverizers

Rumtoo TM Series Pulverizers are designed for high-capacity performance and feature automatic temperature control to ensure optimal processing. Here’s how they work:

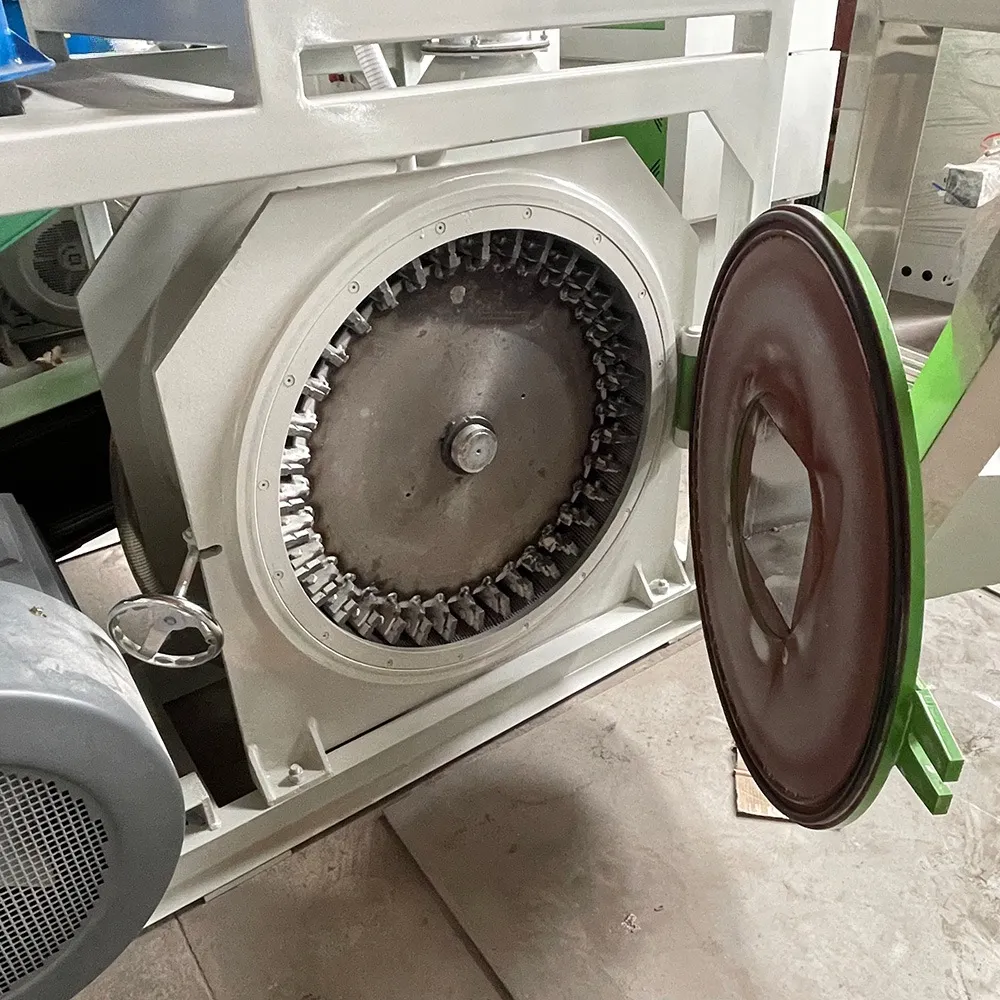

- Fodringsmekanisme: The material to be pulverized is introduced into a fixed, high-speed rotating pulverizer disc via a vibrating feeder.

- Centrifugal Force: An integrated inner disc forces the material through the pulverizer disc, pushing it into an external chamber for discharge.

- Material Conveying System: The material is further assisted by a downstream conveying system, ensuring smooth operation.

| Model | Kraft | Rotating Diameter | Fan Power | Antal blade | Vibration screen diameter | Produktion | Udstyr Vægt |

|---|---|---|---|---|---|---|---|

| TM-500 | 2.2KW | 500mm | 4KW | 12+24 | 800 mm | 150-200kg/h | 1500KG |

| TM-600 | 4KW | 600 mm | 5,5KW | 13+26 | 1000 mm | 200-450kg/h | 2000KG |

| TM-800 | 4KW | 800 mm | 11KW | 15+32 | 1200 mm | 500-800kg/h | 2800KG |

Pulverizer Operation

Unlike other pulverizers, the Rumtoo TM Series operates without the need for a sifter. The final particle size is primarily determined by the tooth configuration and the adjustable gap between the pulverizer discs. However, if required, a sifter can be added to control the particle size more precisely.

Advantages of the Rumtoo Pulverizer

Rumtoo TM Series Pulverizers offer several benefits, making them a preferred choice for many industries:

- High Output: These machines deliver exceptional throughput, making them highly efficient.

- Minimal Thermal Stress: The automatic temperature control reduces thermal stress on the material.

- Longer Disc Life: Pulverizer discs last longer, reducing the need for frequent resharpening and maintenance.

- Easy Adjustment & Replacement: Pulverizer discs can be adjusted or replaced quickly and easily to keep operations running smoothly.

- Omkostningseffektiv: These pulverizers operate economically, lowering production costs.

- Water Cooling System: An internal water cooling system helps maintain optimal temperature during operations, preventing overheating.