Premium Shredding Technology

Explore the core composition and operational principles of our single-shaft shredders, vital equipment designed for efficient waste management. Our machines are engineered to optimise the shredding process through precision engineering and durable construction.

Ansøgninger: Plastic purging, runners, pallets, wood, branches, and bones.

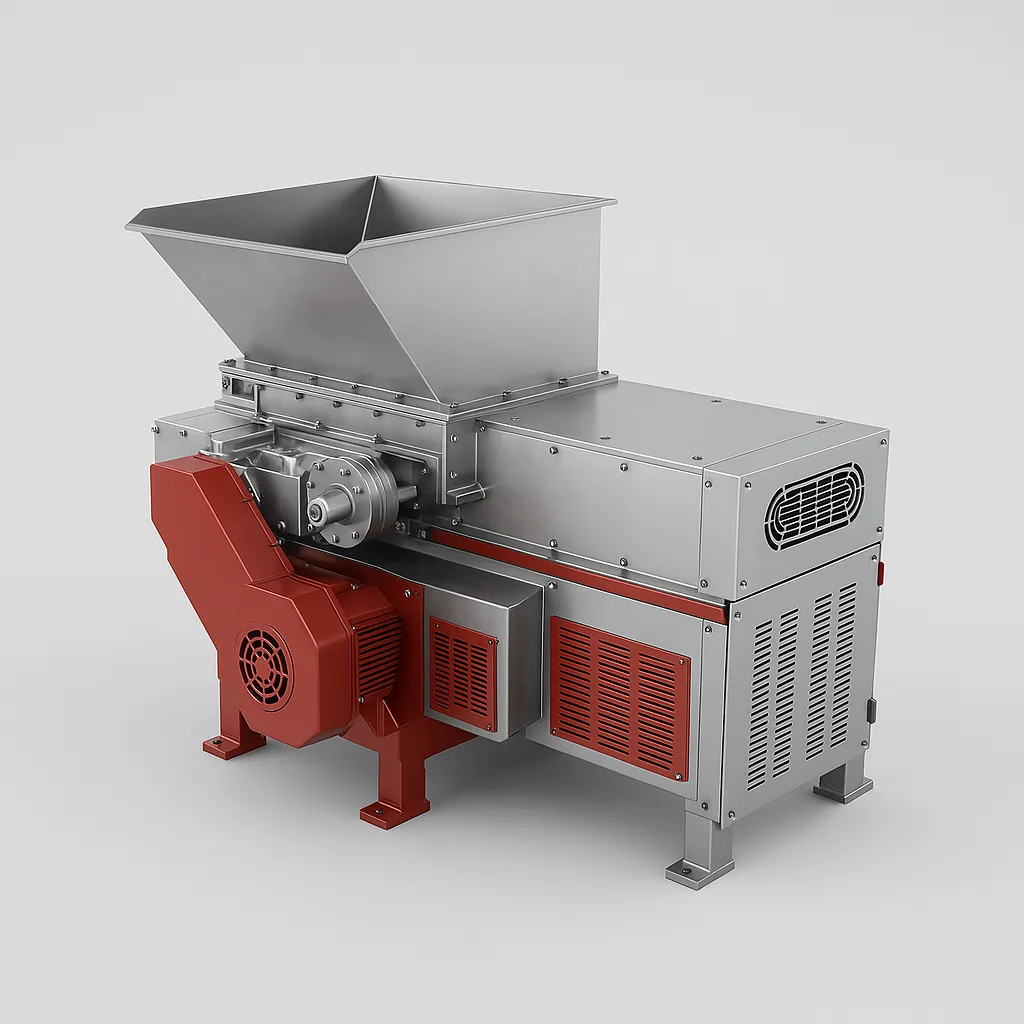

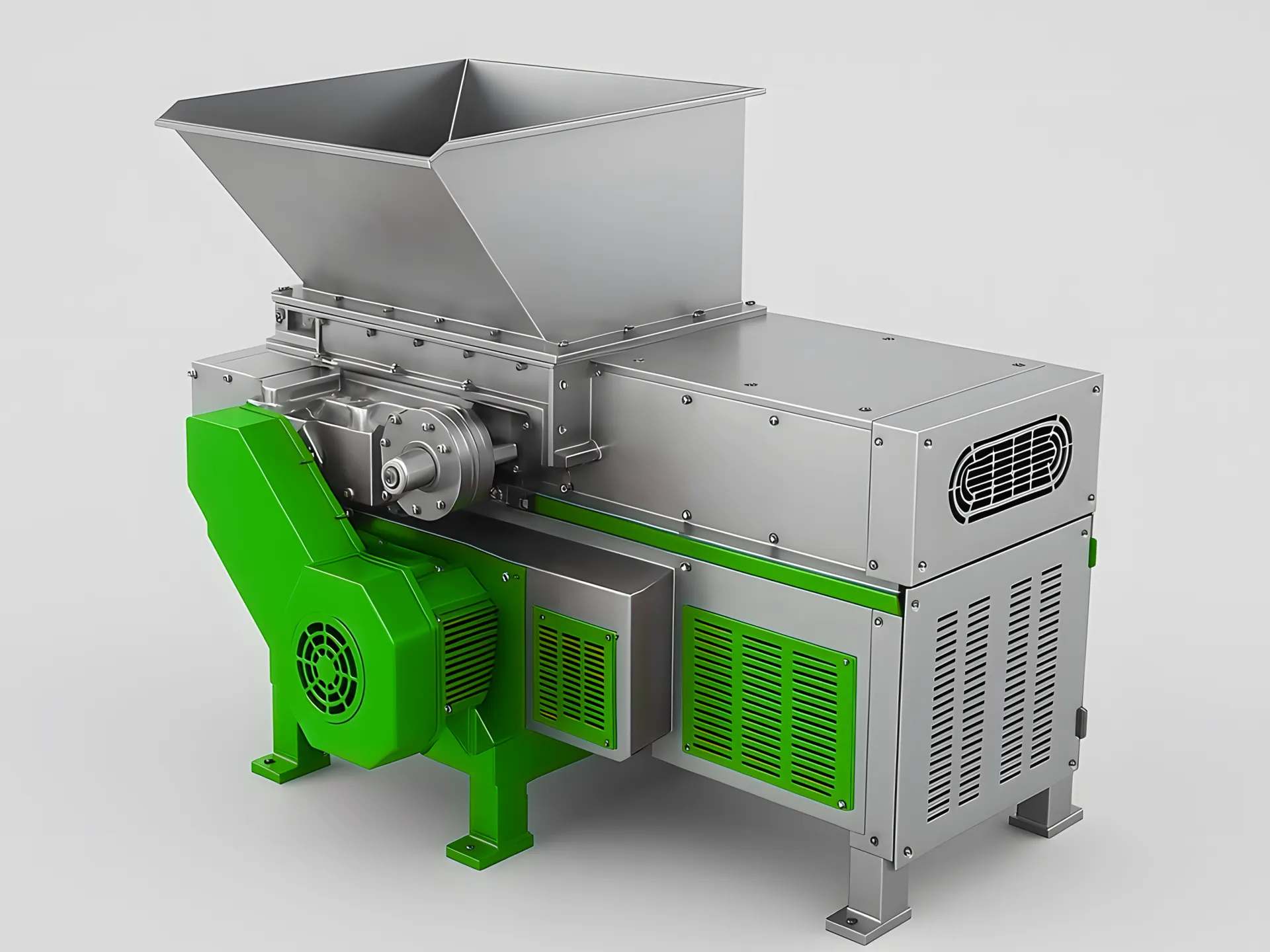

Komponenter i en enkelt-akslet makuleringsmaskine

Our single-shaft shredders are primarily used to break down various waste materials. Here's a detailed look at the main components:

Shaft

Central to the shredder, the shaft drives the blades to effectively crush materials. Typically crafted from robust high-strength steel, it's engineered to endure heavy-duty operation.

Blade

Monteret på akslen skærer, river og sliber disse afgørende elementer inputmaterialerne. Lavet af slidstærkt legeret stål sikrer knivene optimal makulering med forlænget levetid.

Feed Hopper

Denne komponent leder affald ind i makuleringsmaskinen. Dens design varierer baseret på den type materialer, der behandles og de specifikke krav til operationen.

Discharge Outlet

Beliggende ved bunden letter den udledningen af strimlede partikler, designet til at rumme forskellige strimlede materialestørrelser.

Drive System

This includes a motor, reducer, and coupling to transfer power efficiently from the motor to the shredder's mechanical parts.

Driftsprincip

Materialer kommer ind gennem fødetragten, bliver fragmenteret af knivene og drives frem, indtil de når den ønskede størrelse, og kommer ud gennem udløbet. Denne proces involverer flere mekaniske kræfter som friktion og klipning, hvilket sikrer effektiv affaldsnedbrydning.

Key Benefits:

- High-quality, consistent output

- Minimal maintenance requirements

- Adjustable screen size for precise control

- Energy-efficient operation

- Robust construction for industrial environments

Single-Shaft vs Double-Shaft Shredders

| Feature | Enkelt-akslet makuleringsmaskine | Double-Shaft Shredder |

|---|---|---|

| Ideal Materials | Solid, thick pieces (plastic purging, runners, pallets, wood) | Hollow, lightweight plastics (PE films, PP tubes, HDPE drums) |

| Cutting Mechanism | Single rotor with fixed blades | Dual rotors with shear blades |

| Vedligeholdelse | Lower maintenance requirements | Higher maintenance requirements |

| Omkostningseffektivitet | More cost-effective for suitable materials | Higher initial investment, higher throughput |

| Output Uniformity | Good uniformity | Excellent uniformity |

See Our Shredders in Action

Watch our single-shaft shredders process various materials with precision and efficiency.

Tekniske specifikationer

| Model | RTMS-600 | RTMS-800 | RTMS-1000 | RTMS-1200 |

|---|---|---|---|---|

| Kapacitet (kg/h) | 30 kW | 45 kW | 2*37kW | 2*45kW |

| Hydraulisk motorkraft | 4kW | 4kW | 5,5 kW | 5,5 kW |

| Kniv materiale | SKD11 | SKD11 | SKD11 | SKD11 |

| Hovedmotoreffekt | Φ400 | Φ400 | Φ450 | Φ500 |

| Roterende diameter (mm) | 85 | 85 | 80 | 70 |

| Rotationshastighed (rpm/min) | 400-600 | 600-800 | 800-1200 | 1500-2000 |

ENQUIRIES

Alle genbrugsmaskiner leveres med 1 års begrænset garanti.

To receive the latest prices and lead times, please send us a message using the form below.

Kommentarer er lukket.